B軸

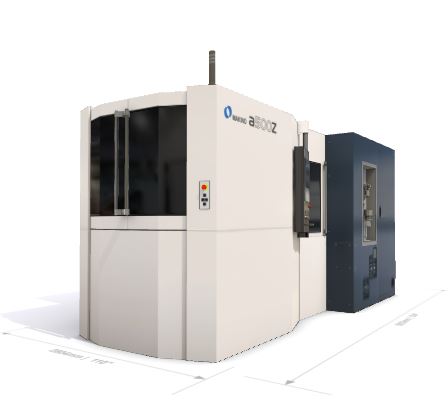

最大工作物寸法はø630mm×高さ500mm、工作物許容質量400kgまで対応します。X軸の移動量は730mm、Y軸750mm、Z軸500mmです。回転軸にはDDモータ(ダイレクトドライブ方式)を採用しました。B軸は360°の連続回転が可能で、革新的な傾斜テーブルのC軸ユニットでは180°の回転が可能です。この回転動作により、パレット上面を主軸中心線と平行(パレット傾斜0゜) / 垂直(パレット傾斜90゜)、そしてこの間を任意に位置決めすることができます。

直行軸の送り速度は毎分60 m 。駆動するボールねじと軸受ブラケットにベッド温度に同調した冷却油を送り、長時間の高速移動による発熱を抑えます。

B軸は毎分45000度、C軸は毎分27000度の回転速度です。この機敏なプラットフォームにより効率の良い機械動作が可能になっています。

14000 回転の高速主軸を標準装備しています。最大出力は37 kW、最大トルクは303 N-mを備えて、広範囲の材料に対応できる理想的な仕様です。小径工具を頻繁に使用する場合には、20000 回転主軸のオプションを用意してあります。

工具マガジンの収納本数は、60本が収納できるリング型が標準仕様です。最大218本を収納するマトリックス型マガジンまで幅広く対応できます。

工作物の取付けは、テーブルが傾斜する軸構成により、立形機同様の水平段取りが可能です。またa1nx の自動パレット交換装置を採用しており、交換は短時間で済みます。

本機にはユーザーに優しいタッチスクリーンインターフェース、高度な工具データ管理、そしてマキノが特許を有するスーパーGI.5高速加工制御システムなどが搭載された制御装置プロフェッショナル6 が標準装備されています。

B軸

360°

C軸

180°

主軸回転速度

50 ~ 14000 min-1

特別仕様:20000 min-1

主軸端(呼び番号)

BT40(7/24テーパ#40)

特別仕様:HSK-A63

早送り速度

60000 mm/min(X・Y・Z 軸)

45000°/min(B 軸)

27000°/min(C 軸)

切削送り速度

1 ~ 50000 mm/min(X・Y・Z 軸)

1 ~ 45000°/min(B 軸)

1 ~ 27000°/min(C 軸)

最大ワーク寸法

Φ630 mm × 500 mm

最大積載質量

400 kg(パレット質量は除く)

工具収納本数

60 本

特別仕様:133、218、313 本

工具最大長さ

510 mm(制限あり)

工具最大径

70 / 170 mm(制限なし / あり)

工具最大質量

12 kg

仕様により異なりますので、詳細は必ずお問い合わせください。

Copyright © 2024, Makino All rights reserved